Packaging regulations, material availability, and industry standards are shifting quickly. As a result, CPG packaging changes are becoming harder to track and plan for. As a proactive supply chain partner, our role is to help you anticipate what’s coming and understand how it impacts your packaging decisions amid evolving CPG packaging regulations.

Below is a snapshot of several developments we’re actively monitoring this year. Throughout the year, we’ll explore these topics to help brands stay ahead of new regulations and other changes.

Paper Industry Closures and Supply Stability Driving CPG Packaging Changes

Mill closures continue across the paper industry, and we expect that trend to continue. For brands using paper-based packaging, the biggest concern is supply instability. Fewer mills leave customers with fewer options, longer lead times, and greater risk if a supplier closes.

To mitigate risk, CPG brands should be using benchmarking tools to understand closure risk within their current paper supply. From a label perspective, we can work with you to qualify alternate materials so you have options in place before disruptions occur.

You can read more on this topic here.

Synthetic Food Dyes Under Scrutiny

Regulatory pressure around synthetic food dyes is increasing. The FDA has announced that food and beverage products must be formulated without FD&C Red No. 3 by January 15, 2027. Six additional dyes are expected to be banned by the end of 2026.

For brands, this means evaluating natural alternatives and reviewing disclosures and marketing claims to avoid misleading consumers. At the same time, packaging design choices play a bigger role as formulations change. Solutions like shrink sleeves help maintain vibrancy and shelf impact even as formulations change.

There is more information on this ban on the FDA’s website.

State PFAS Laws and Regulations

PFAS (perfluoroalkyl and polyfluoroalkyl substances) are synthetic “forever chemicals” that do not easily break down in the environment. Across the U.S., states are shifting from voluntary reductions to mandatory reporting and labeling requirements throughout 2026, with several significant mid-year deadlines.

Minnesota is requiring manufacturers to submit PFAS usage reports by July 1, 2026, and New Mexico may begin reporting on the same date if its proposed rules move forward. A full list of 2026 state PFAS laws and regulations can be found here. Like EPR laws, these deadlines often apply based on where you sell products, not where your company is located.

For CPG companies, these regulations present new challenges, particularly for brands selling across multiple states. To prevent disruptions, it’s essential to stay ahead of evolving PFAS reporting and labeling mandates. As your custom label printing partner, Steinhauser is committed to supporting whatever changes come next, whether that involves design adjustments or sharing information you may need for compliance.

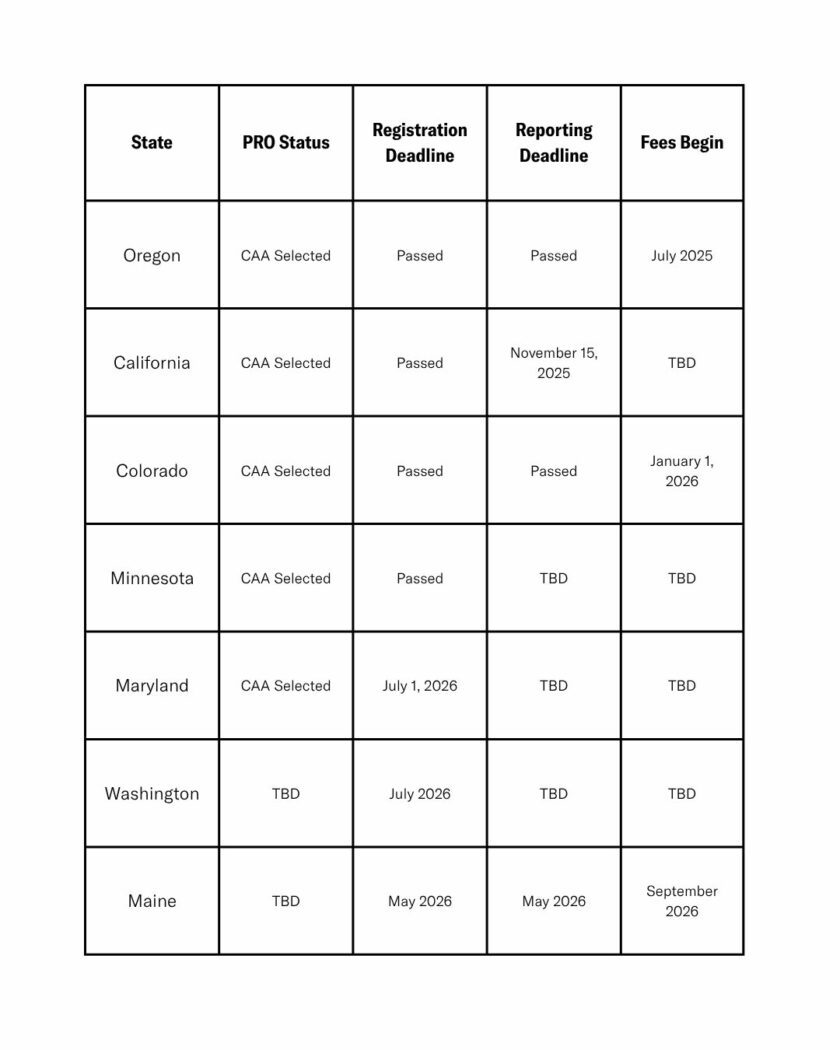

Extended Producer Responsibility (EPR) Rollouts

EPR laws continue to expand as additional states adopt programs. Fees are currently being collected in Oregon and Washington. Producers will need to register in Maine by May 2026, and in Maryland and Washington by July 1, 2026.

These laws influence packaging design, material choices, and long-term cost structures. Staying informed and planning ahead is critical. We’ve published previous blogs outlining producer obligations and deadlines, and how EPR is shaping packaging decisions. Meanwhile, we continue to track updates through organizations like Circular Action Alliance.

GS1 Sunrise and the Future of Barcodes

GS1, the organization behind the original UPC barcode, is rolling out GS1 Sunrise, an initiative focused on expanding the use of QR codes and other two-dimensional barcodes. By the end of 2027, retailers are expected to ensure their POS systems can read both UPC and 2D barcodes.

There are no formal requirements for CPG brands yet, and UPCs remain necessary with no sunset date announced. Even so, brands should evaluate where 2D barcodes may fit into their packaging. The good news is that 2D barcodes offer significant benefits for the entire lifecycle of the product, such as enhanced trackability, consumer trust, and security. We’re ready to support customers as those conversations turn into action.

Planning Ahead for CPG Packaging Changes Reduces Risk

Each of these CPG packaging changes demonstrates how decisions are becoming more complex. At Steinhauser, we help you understand the impacts of regulatory changes and support the packaging adjustments needed without disruption. If you’re evaluating materials or redesigning packaging, we’re here to help you avoid surprises.

Found this useful? Join our monthly newsletter for practical tips, updates, and a behind-the-scenes look at Steinhauser. No spam, ever.