Markets We ServE

From concept to shelf, Steinhauser works with all customers to create unique and exceptional packaging solutions that will drive their success.

Personal hygiene and beauty care items such as shampoos, conditioners, deodorant, skin moisturizers, hand sanitizers, protein powder, supplements and more.

The Kind Sanitizer Company

Wipe Containers

Pressure Sensitive Labels

Digital Printing: white BOPP with matte laminate

The Kind Sanitizer Company

Sanitizer Gel

Pressure Sensitive Labels

Digital Printing: white BOPP with matte laminate

The Kind Sanitizer Company

Sanitizer Gel

Pressure Sensitive Labels

Digital Printing: white BOPP with matte laminate

SoF

Hand Wash

Pressure Sensitive Labels

Digital Printing: white BOPP with matte laminate

Kirk’s

3-in-1 Head to Toe Cleanser

Pressure Sensitive Labels

Digital Printing: white Semi-gloss paper with matte laminate

Household cleaners including oven and drain cleaners, antibacterial cleaners, surface cleaners, floor polish, dish soap, dish detergent and more.

Procter & Gamble

Dawn Powerwash

Pressure Sensitive Labels

Flexo Printing: Metallic BOPP with spot matte/gloss varnish and white tactile varnish

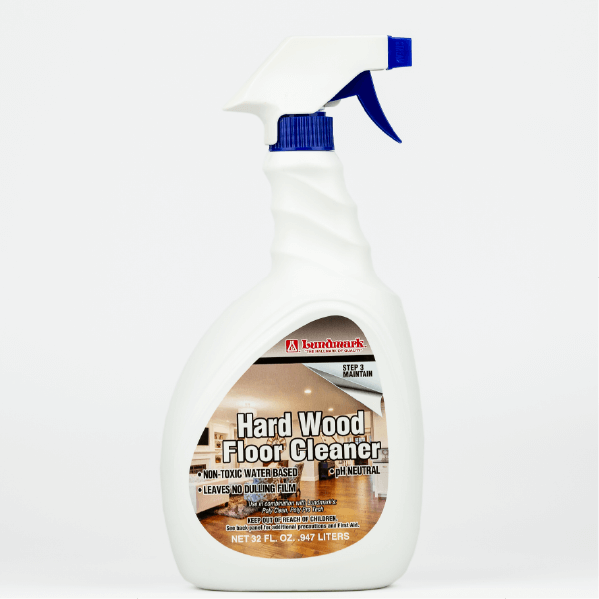

Lundmark

Hard Wood Floor Cleaner

Pressure Sensitive Labels

Digital Printing: semigloss paper with gloss varnish

Poo-Pourri

Original Citrus

Shrink Sleeves

Flexo Printing: PETg with surface matte varnish

Poo-Pourri

Original Citrus

Shrink Sleeves

Flexo Printing: PETg with surface matte varnish

Procter & Gamble

Mr. Clean

Pressure Sensitive Labels

Flexo Printing: semigloss paper with gloss varnish

Procter & Gamble

Swiffer Shrink Sleeves

Flexo Printing: PETg film

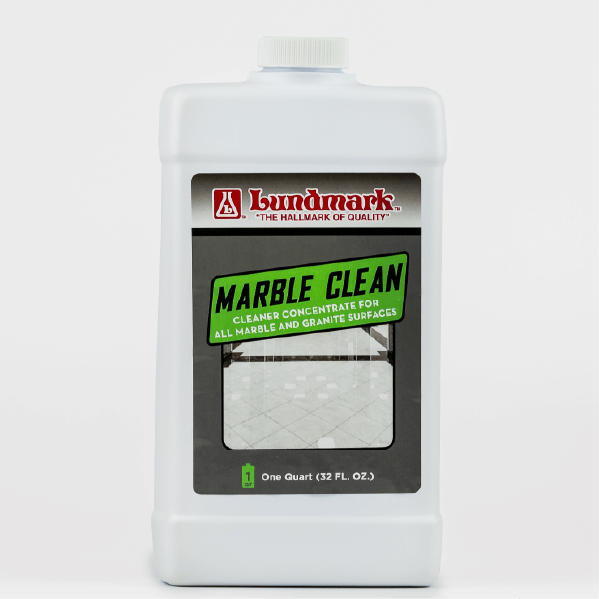

Lundmark

Marble Clean

Pressure Sensitive Labels

Digital Printing: semigloss paper with gloss varnish

Energy drinks, juices, kombucha, protein shakes, meal replacement drinks, nutritional drinks, vitamin drinks, hydration drinks and all other multi-use and ready-to-drink beverages.

Buoy

Hydration Drops

Shrink Sleeves

Digital Printing: PETg film

Miss Mary’s

Pressure Sensitive Labels &

Shrink Sleeves

Digital Printing: Semigloss paper with laminate

and PETg with cover up foil

Campfire Foods

Tea and Lemonades RTD

Pressure Sensitive Labels

Digital Printing: metallic BOPP with matte laminate

Select Squeeze

THC Beverage Enhancer

Shrink Sleeves

Flexo Printing: PETg film

Vive Punch

Vive Punch 12oz Sleek Cover Up

Shrink Sleeves

Flexo Printing: PETg with cover up foil

Hard liquor and distilled beverages such as Vodka, Tequila and Liqueurs in both multi-use and ready-to-drink (RTD) formats.

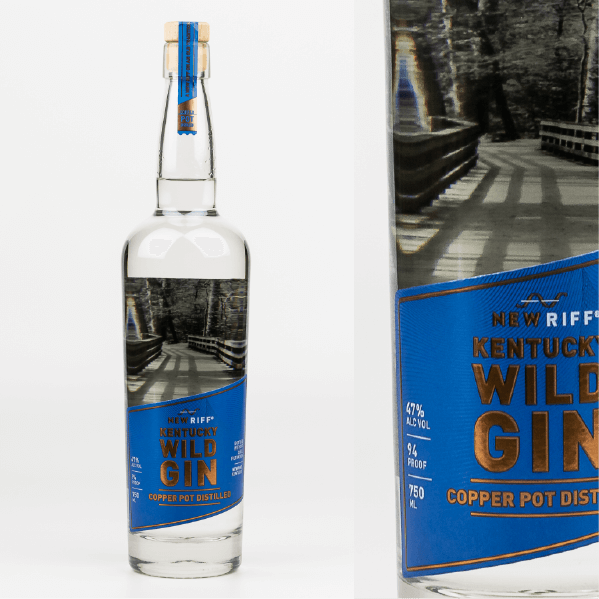

New Riff

KY Wild Gin

Pressure Sensitive Labels

Flexo Printing: metallic paper with tactile varnish and spot matte varnish laminated to clear BOPP

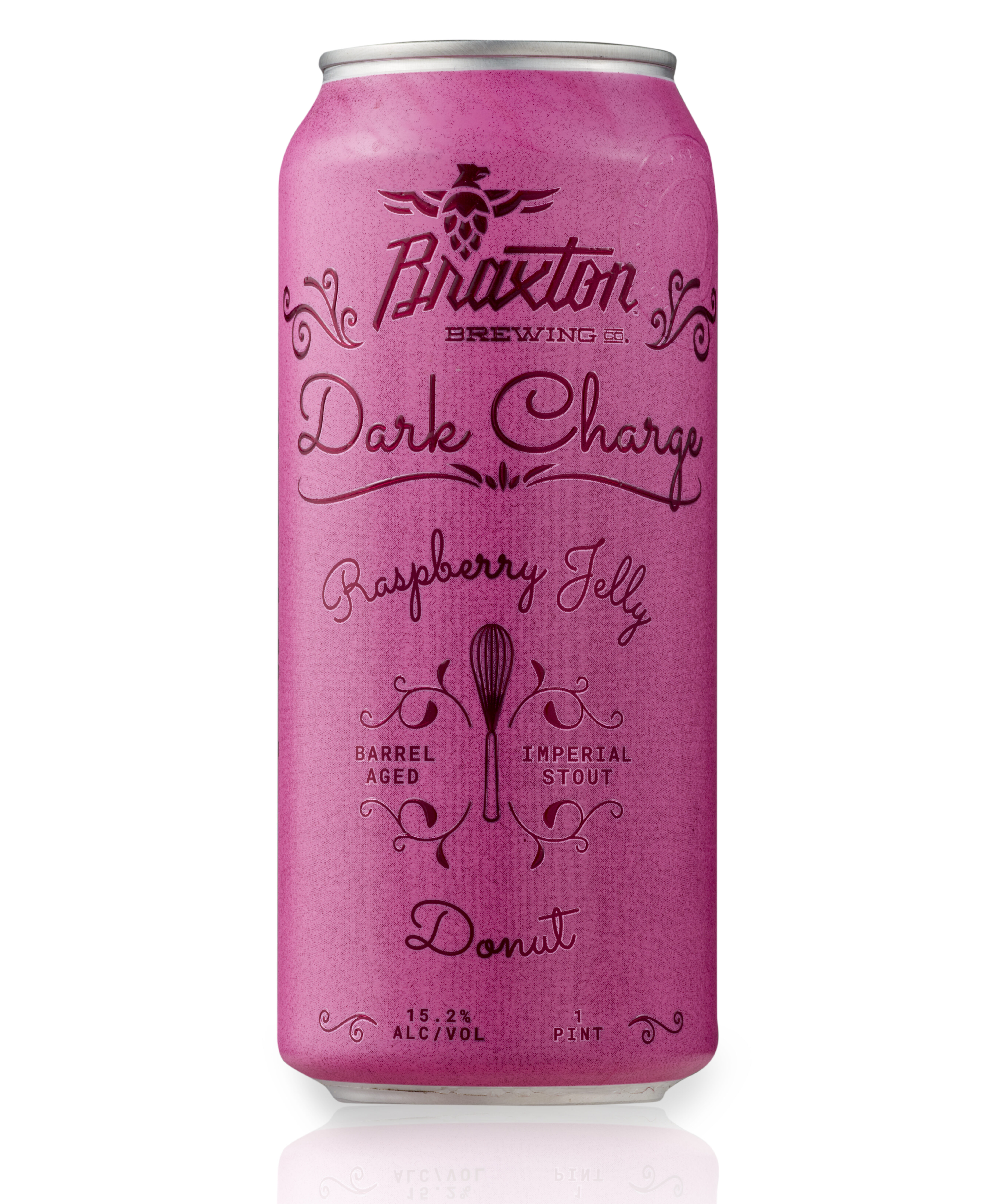

Braxton Brewing

16oz Can Shrink Sleeves

Flexo Printing: PETg film with surface matte varnish and clear tactile varnish

Boone County Distilling Co.

Tanner’s Curse Whiskey

Pressure Sensitive Labels

Flexo Printing: White BOPP with foil

Wooden Cask

12oz Bottle

Pressure Sensitive Labels

Digital Printing: metallic BOPP with matte Braxton Brewing

16oz Can Shrink Sleeves

Flexo Printing: PETg film with surface matte varnish and clear tactile varnish

West Side Brewing

Braille Ale

Pressure Sensitive Labels

Flexo Printing: White BOPP with tactile varnish to create braille